Thinking about designing your zinc roof to include rooflights? This article talks about the key questions you should ask before you start.

The advice here is for zinc roofing and focused on elZinc detailing. It is worth remembering that whilst the details and advice may be suitable for other metals and for other manufacturers’ zinc products, you should contact us for advice about these as the information is not always the same and manufacturers differ in their requirements.

Rooflights in Zinc Roofing – the Key Questions

There are three key questions which always come up when we talk to architects about rooflights in metal roofing:

- What is the Roof Pitch?

- What are the Width Limits?

- What are the Depth Limitations? (particularly with Flush or Sunken Rooflights).

Let’s deal with them one at a time.

Rooflights are a form of penetration to your zinc roof, and as such need to be designed and installed with care, so as not to affect the overall integrity of the roof and the protection it provides to the building. – FTMRC UK Guide to Good Practice

1. Roof Pitch and Rooflights in Zinc Roofing

One of the first questions we will ask you is, “what pitch is the zinc roof?”

We wrote about the minimum pitch for standing seam zinc roofing here. The challenge is water ingress in the seams, which becomes more likely as the pitch lowers. During heavy rain, water can build up at the roof to the level of the overlap on the standing seam and this can cause the water to be sucked into the construction via capillary action.

Make sure you can still drain water off

The higher the pitch, the more effective your roof is at draining off water. With rooflights, the issue of water ingress can be greater due to the rooflight acting as an obstacle to rainwater getting off the roof.

Make sure your rooflight is approved for low pitch

At lower pitches, unless the water is managed efficiently there is a risk of ponding water at the head of the rooflight, if only temporarily. As a result, some rooflight manufacturers specify minimum pitches, so make sure your choice of rooflight will comply with your choice of roof pitch.

If you need advice on which rooflights you could use, we are of course happy to assist; just drop us a line.

2. What are the Width Limits for Rooflights in Zinc Roofing?

Another question we will commonly ask is, “how wide will your rooflights be?”

Once again, this is due to the need to drain water off the roof effectively. If the rooflight is wide and you are breaking more than say, three seams, diverting water around the rooflight becomes a problem, simply due to the quantity of water involved.

No water running over the face of the rooflight

No matter what the size and position of the rooflight, your objective should be to allow all the water to drain away around the sides – letting water run over the face of the rooflight is not good practice.

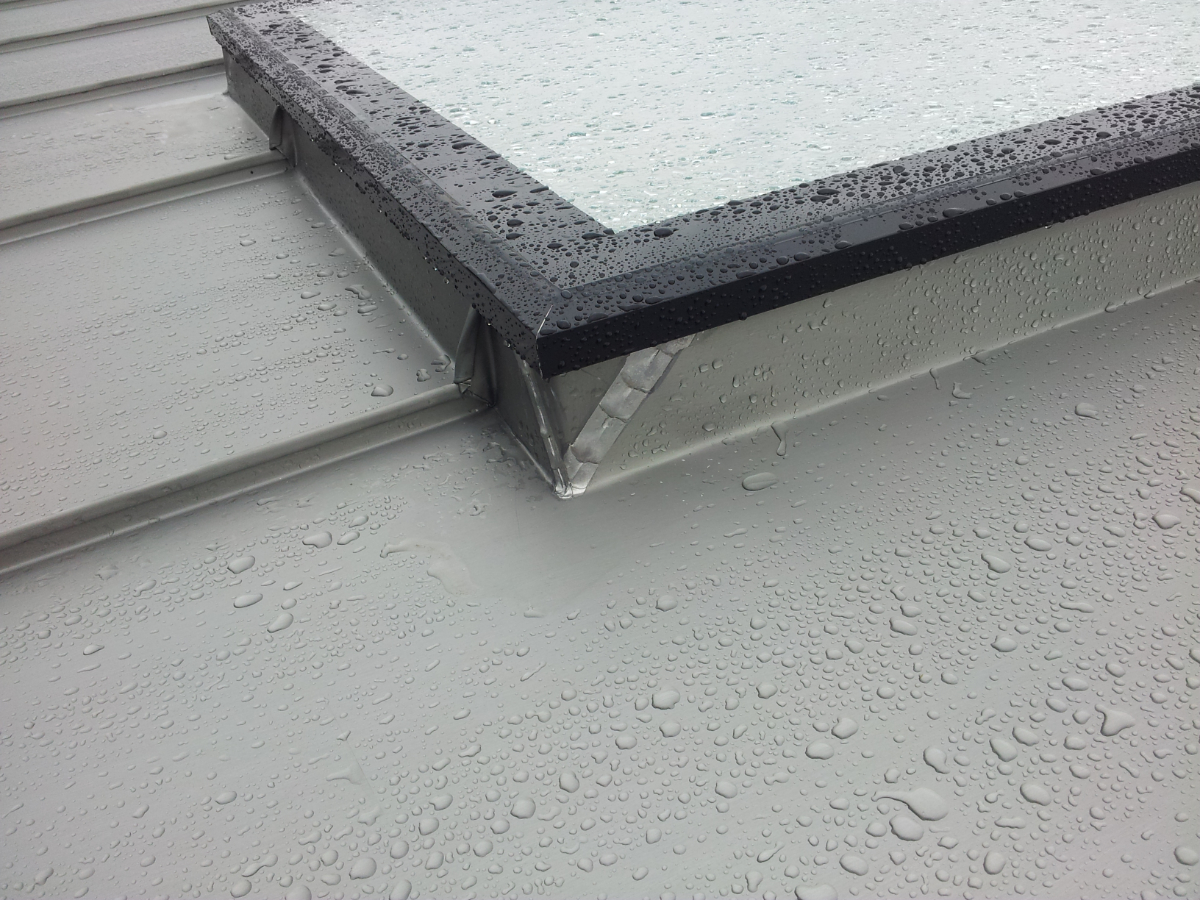

The FTMRC recommends that rooflights are mounted on a weathered timber upstand a minimum of 100mm high and 50mm wide. Some manufacturers will provide flashing kits to cover the upstand, or we can supply them for our installers.

100mm upstand shown at the foot of a rooflight

Soldered or Welted installation?

Depending on the pitch of the roof, the installation will be soldered (usually below 14º) or welted (above 14º).

On a soldered installation, the seams will be folded flat and soldered 300mm above the rooflight together with a deflector fillet, to allow the water to flow horizontally around the edge of the rooflight.

On a welted installation, the standing seams will stop a distance above the rooflight and a continuous flashing (known as a back gutter) introduced, again with a deflector fillet.

In either case you’ll need some space above the rooflight to allow for these changes to the standing seam, which affect where you can position them. The distance required will depend on the roof pitch and size of the rooflight – contact us for advice.

Back gutter over a welted rooflight (above 14º)

Rooflights above one another?

If you want to install a series of rooflights above one another, bear in mind that these pose an additional challenge and greater risk of flooding the surrounding standing seams.

As always it’s a good idea to talk to us about what you are trying to achieve – it’s likely we’ll have some ideas on how to get there.

3. Can I have Flush or Sunken Rooflights in my Zinc Roof?

The third question concerns the depth of your roof, if you want to incorporate flush rooflights, also known as sunken rooflights.

If you don’t want an upstand on your rooflight, if you want the surface to be flush with the roof surface, it is still good practice not to allow water to flow over the top, and therefore you’ll need a gulley around the back and sides to divert the water in place of the upstand.

How to fit a gulley in your roof structure?

The space to incorporate this gulley has to be accommodated within the depth of the roof, and therefore it may involve adapting the insulation and maintaining the ventilation space, even lowering or cutting into the rafters.

Make sure you can achieve your target U-values!

All too often if you’re trying to achieve a particular U-value in the roof, cutting in the rooflights may make that just that much more difficult. Whilst you can use alternative insulation materials around the area, this can also have a knock on effect on the cost.

Be prepared for the higher cost of flush rooflights

Sunken or flush rooflights are by their nature more expensive. There are implications for the structure, the insulation, and to incorporate the sunken gulley.

However, we recognise the desire to achieve a flush finish, and work with architects to make this possible within best practice. They key is to involve us early. Talk to us about your plans, and we’ll help you head off any nasty surprises later.

Rooflights in Zinc Roofing – talk to the experts

We’re keen to share our expertise on rooflight installation with you, because everyone wins. If you know what to consider, you’ll make the right decisions early, and it saves us having to unpick those decisions later.

If you’ve got a zinc roofing project which you’d like to incorporate rooflights into, get in touch. We’re just an email or phone call away.

About the author – SIG Zinc and Copper Team

We are the team at SIG Zinc & Copper. We design and supply zinc, copper, aluminium and stainless steel roofing and cladding products all over the UK. We also publish blog posts! We're part of SIG Roofing. With over 120 branches nationwide, SIG Roofing is the largest supplier of roofing materials in the UK, providing our customers with impartial advice on the right roofing solution for their projects.

Recent Comments